Within the realm of die-making, rotary dies and flat dies stand as two masters, each possessing unique strengths. Neither is inherently superior; the key lies in making the most judicious choice based on your product characteristics, production volume requirements, and cost budget.

As a vital link in the die-cutting supply chain, the precision and efficiency of the Rotary dies machine directly impact the quality of the die. We understand that the exceptional die is the crucial starting point for enhancing your product competitiveness and production efficiency.

Whether you ultimately choose rotary dies or flat dies, the core element—a high-precision die—remains indispensable.

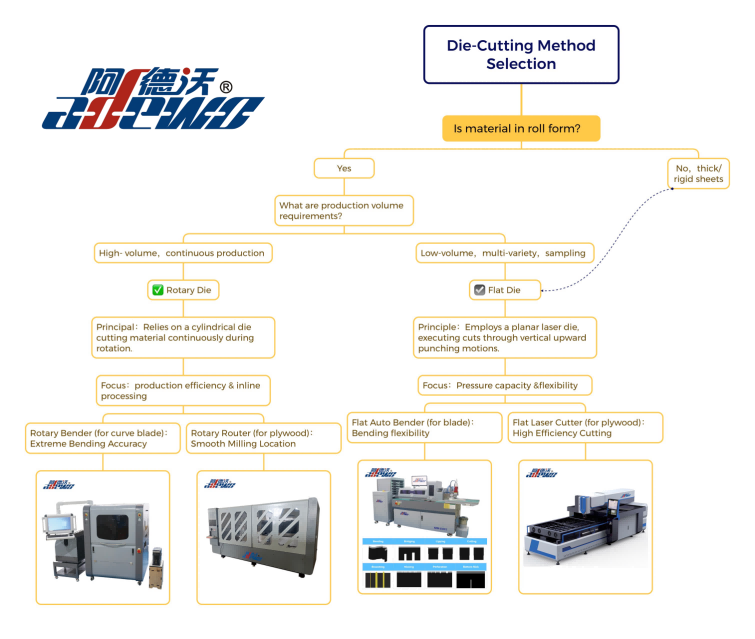

Different product characteristics and production volume requirements lead to different die-cutting method selections.

Rotary dies, characterized by its high-speed continuous production, is particularly suited for processing large-volume roll materials.

Self-adhesive label industry: This represents the most classic application domain for Rotary dies. Whether for food labels, pharmaceutical labels, or electronic labels, the demands for high speed and precision align perfectly with the characteristics of Rotary dies.

Electronics Industry: Precision components such as smartphone spacers, flexible printed circuits (FPC), insulating materials, and dust filters require Rotary die’s high precision and clean cut surfaces.

Medical and Hygiene Products: Band-Aids, medical tapes, and disposable hygiene items (e.g., components of nappies) demand high volumes and stringent hygiene standards, which Rotary dies fulfil perfectly.

Flexible Packaging Industry: Easy-tear openings for food pouches, forming of flexible packaging bags, etc.

Flat dies proves indispensable in another domain through its immense punching force and flexible die-changing capabilities.

Packaging Boxes and Printed Materials: High-end gift boxes, mobile phone cases, wine boxes, book covers, etc., typically utilize thicker cardboard or specialty papers. Achieving precise die-cutting requires substantial punching force, making Flat dies the ideal solution.

Industrial and Automotive Components: Sealing gaskets, rubber parts, soundproofing foam, automotive interior fittings, etc., often involve thicker or harder materials demanding the robust pressure of Flat dies.

Footwear Materials and Garment Accessories: Die-cutting leather uppers, soles, handbag components, and garment interlinings is effortlessly handled by Flat dies.

Home-ware and Sporting Goods: Yoga mats, floor mats, sponge-based home accessories, and children's interlocking floor puzzle mats.

For roll-fed products demanding ultimate efficiency and large-scale continuous production, Rotary dies are the undisputed tool of choice. Conversely, for heavy-duty, diverse thick materials and intricate products, Flat dies demonstrates irreplaceable value.

|

Rotary dies |

Flat dies |

| (1) Customized Solutions for Extreme Reduction of Material Waste | (1) Customized Solutions for Different Design |

|

(2) Special Knifing Technique to Ensure Excellent Cutting Results |

(2) Suitable for Multiple-Cavity Jobs with High Accuracy Performance |

|

(3) Special Ejecting/Rubbering Technique Enables High Efficiency in Waste Removal |

(3) Special Ejecting Technique Enables High Efficiency in Ejections and Ensures Constant High Machine Speed |

|

(4) Maximum Machine Speed Featuring Quick Turnover Time |

(4) Perfect Customized Stripping System and Optimize Waste Removal |

|

(5) Perfect for High Volume Projects with Consistent Cut |

(5) Creasing Technology Provides Excellent Creasing Quality |

|

(6) Creasing Solutions Technology Ensures Excellent Creasing Quality |

(6) High Durability and Excellent Results for Medium to Long Run Jobs |

|

(7) Reduce in Machine Downtime and Increase in Productivity |

(7) Convenient to Re-knife |

Whether your choice is rotary or flatbed, the essence lies in high-precision cutting dies. We specialize in curved die-cutting machine manufacturing, dedicated to providing die manufacturers and die-cutting departments across packaging, printing, electronics, automotive components, and other industries with high-precision, high-efficiency, and highly stable automated curved die-cutting equipment. Whether it's the curved dies required for Rotary dies or the flat dies needed for Flat dies, our technology offers robust support. Should you have an interest in die-cutting equipment or be considering entering the die-cutting industry, we warmly invite you to discuss your requirements with us. We are confident we can provide you with the most cost-effective solution.

Rotary Bender: https://www.china-adewo.com/rotary-die-formes-auto-bender-machine.html

Rotary Router: https://www.china-adewo.com/cnc-rotary-router.html

Flat Auto Bender: https://www.china-adewo.com/auto-bender-machine.html

FLat Laser Cutter: https://www.china-adewo.com/600-watts-gantry-type-die-boards-die-making-laser-cutting-machine.html

Inquiry: sales@china-adewo.com

We hope this article offers some clear guidance on your journey through the world of die-cutting. May each choice you make be precisely tailored to your needs, delivering efficiency and accuracy!