In the packaging, printing, and die-cutting industries, a stripping die is a critical and essential component of a cutting die system. Its "existence" or purpose is fundamental to an efficient and clean cutting process.

Here’s a breakdown of its role and why it is indispensable:

After the die blade cuts through the material (like cardboard, foam, adhesive sheets, etc.), the cut pieces and the surrounding waste material (the matrix or skeleton) often remain tightly wedged on the die blades. The stripper plate's primary job is to separate this waste material from the die blades as the die is lifted, ensuring the good, cut-out parts (the "product") remain on the press bed or are cleanly ejected.

(1) Prevents Material Lifting: Without a stripper plate, the waste sheet would stick to the die and lift up with it, causing misalignment, double cuts, and production stoppages.

(2) Ensures Clean Stripping: It applies an even, controlled force to push the waste material off the blades, resulting in a clean separation. This is especially crucial for intricate designs or sticky materials (like adhesives or foam).

(3) Protects the Material: It holds the material flat during the cutting stroke, preventing wrinkles or shifting, which ensures precise cuts.

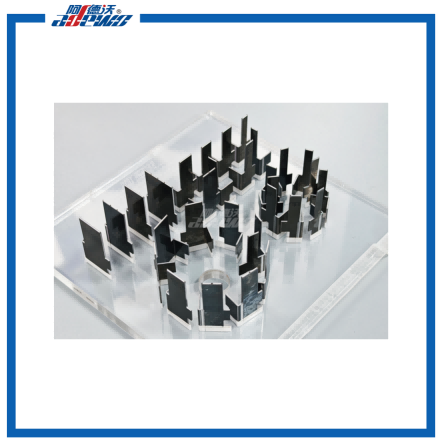

The stripping die is a sturdy plate (often made of acrylic, plywood, or metal) that sits around the die blades.

It moves independently.

Downstroke: The die descends. The stripper contacts the material first, pinning it flat before the blades cut through.

Upstroke: As the die lifts, springs or ejector mechanisms push the stripper downward relative to the die block. This motion pushes the waste material off the blades, leaving it behind.

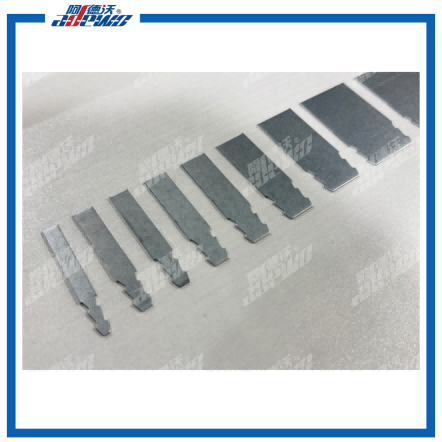

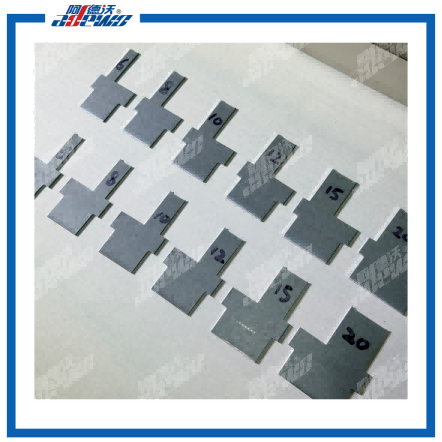

Samples:

Working Video:

(2) Auto Bending

Samples:

Working Video:

In summary, the existence of the stripper plate is not optional; it is a vital part of the die that guarantees the reliability, precision, and speed of the die-cutting process by mechanically clearing away waste material after each cut.