|

Weld Way |

Sample |

Spot Shape |

|

Laser Weld |

|

|

|

Laser Weld |

|

|

|

Laser Weld |

|

|

|

Laser Weld+Wire Feed Weld |

|

|

|

Wire Feed Weld |

|

|

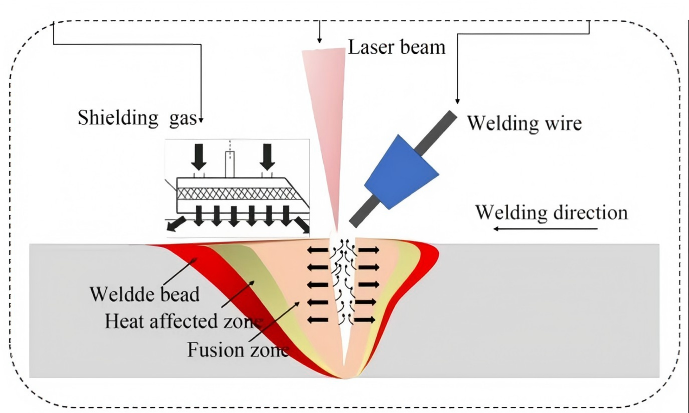

The advantage of laser welding is that it uses high-energy laser to irradiate the surface of the material, causing it to melt quickly thus achieving the purpose of high-efficiency welding. (Laser weld sample as reference)

Adding a wire feeder on the laser welding machine creates the more powerful laser wire-fed welding.

Wire feeder

The wire feeding weld minimizes the heat-affected zone and reduces distortion and residual stress, enables deep penetration, and the filler wire can help refine the microstructure of the weld metal. (Wire feeding weld sample as reference)

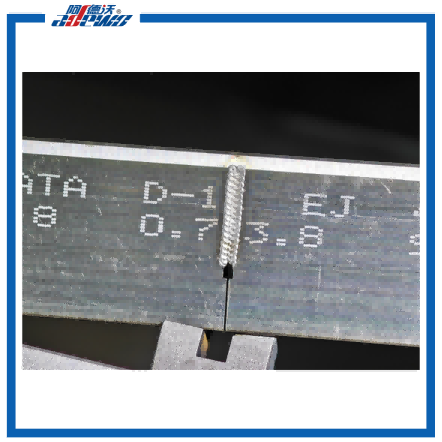

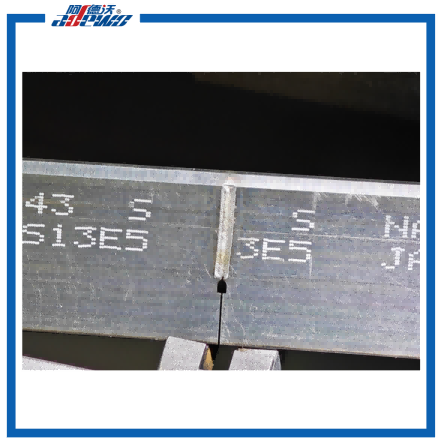

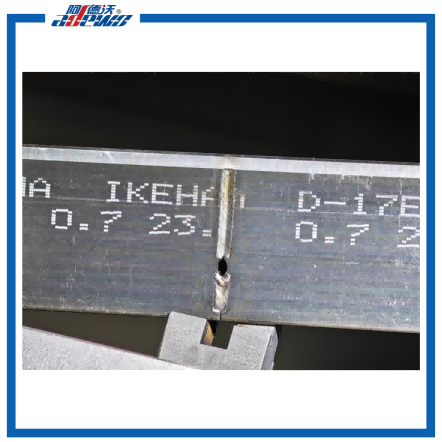

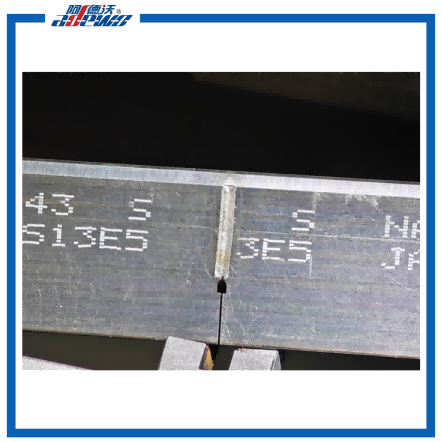

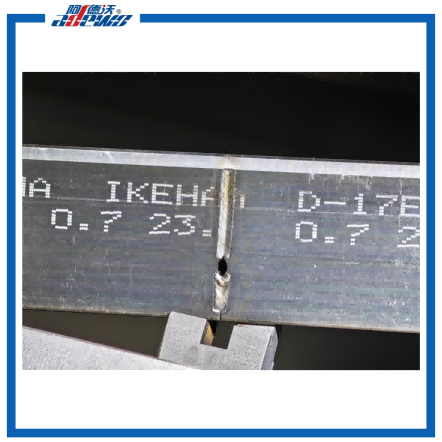

As can be seen from the comparison images as following, the weld joint of the wire-feed welding sample protrudes due to the addition of extra metal material.

In welding process, argon acts as a shielding gas, does not react with the metal, and is not soluble in the metal. It can isolate the oxygen, nitrogen, and hydrogen in the air from the arc and the zone, reduce the loss of alloy elements, and obtain a dense, non-spatter, high-quality weld.